The Future of Cleaning Technology: Innovations in Brush Machines

The Future of Cleaning Technology: Innovations in Brush Machines

Blog Article

The cleaning industry is undergoing a significant transformation, fueled by advancements in technology that are revolutionizing how we maintain cleanliness across various sectors. As the demand for efficient and effective cleaning solutions continues to rise, innovative brush machines are becoming essential tools in both industrial and commercial cleaning applications. These machines not only enhance the speed and efficiency of cleaning processes but also ensure that results are consistent and of high quality.

Brush Making Industry Insights

One of the leading names in this evolving landscape is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of specialized experience, this company has honed its expertise in producing advanced 2-5 axis machines. Their commitment to quality and technical innovation has positioned them as a key player in the brush machine manufacturing industry. As we explore the future of cleaning technology, it becomes clear that companies like Jiangmen Meixin are paving the way for a cleaner and more efficient world.

Overview of Jiangmen Meixin Comb Brush Making Machine

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a leader in the brush machine industry, boasting an impressive 37 years of production experience. The company specializes in the design and manufacturing of advanced 2-5 axis machines that cater to a wide range of brush and comb production needs. With a focus on innovation and quality, Meixin has built a solid reputation for delivering reliable and efficient machines to its clients.

Over the years, Jiangmen Meixin has accumulated extensive technical expertise, allowing it to stay at the forefront of cleaning technology. The company continually invests in research and development to enhance its manufacturing processes and product offerings. This commitment to advancement ensures that Meixin's machines meet the evolving demands of the brush production market, making them a preferred choice for manufacturers globally.

Meixin's success can be attributed to its deep understanding of the brush-making process and its dedication to customer satisfaction. The company works closely with its clients, providing tailored solutions that address specific operational requirements. This customer-centric approach has not only fostered strong partnerships but also propelled Jiangmen Meixin to become a vital player in shaping the future of cleaning technology through innovative brush machine designs.

Innovations in 2-5 Axis Technology

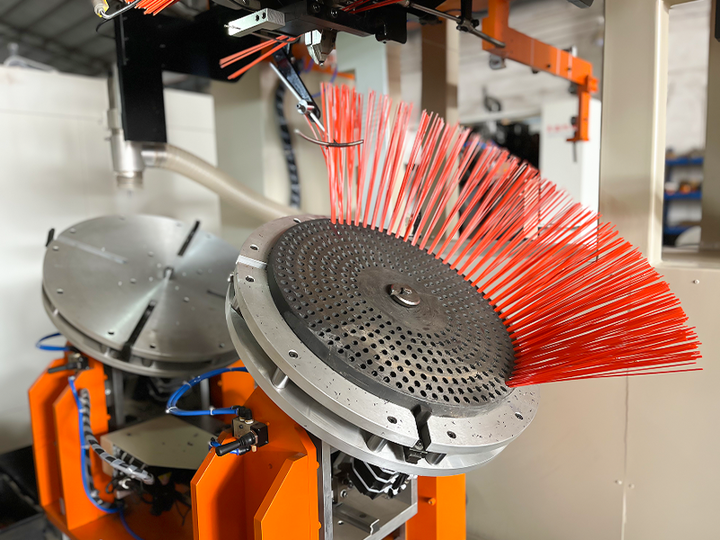

The evolution of 2-5 axis technology has significantly transformed the brush manufacturing industry. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has been at the forefront of this change, leveraging 37 years of production expertise to enhance the capabilities of their machines. These innovations allow for more complex brush designs and a higher degree of precision, catering to the diverse needs of various industries. With advanced motion control systems, manufacturers can now produce brushes with intricate shapes and bristle arrangements that were previously unattainable.

In addition to design flexibility, enhanced automation features have been a major focus in the development of 2-5 axis machines. By incorporating smart technology, factories can optimize their production processes, reducing labor costs and minimizing human error. Jiangmen Meixin's commitment to innovation has led to machines that offer faster cycle times and improved efficiency, resulting in increased productivity and higher output quality. This shift not only streamlines operations but also allows manufacturers to respond swiftly to changing market demands.

Furthermore, the integration of advanced materials and eco-friendly practices is shaping the future of brush manufacturing. Jiangmen Meixin's machines are designed to work with a variety of sustainable materials, enabling companies to meet the growing consumer demand for environmentally responsible products. As manufacturers adopt these innovative technologies, they position themselves to thrive in a rapidly evolving market while contributing to a more sustainable future for the cleaning technology sector.

Impact of Experience on Production Quality

The experience of a company plays a crucial role in determining the quality of its products. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has built a reputation over 37 years in the industry, allowing it to refine its processes and innovate continuously. This extensive experience fosters an understanding of the nuances in brush machine production, leading to better design, enhanced functionality, and improved durability of the machines produced.

With a commitment to quality, the technical accumulation achieved by Jiangmen Meixin ensures that each machine is not just built to meet market demands but also to exceed them. Veteran workers and engineers understand the intricacies of 2-5 axis machines, leading to more precise and efficient operations. Their knowledge significantly reduces the risk of defects, ensuring that the final products copyright strict quality standards, which is essential for customer satisfaction and long-term success.

Furthermore, experience allows for effective troubleshooting and problem-solving, ensuring that production runs smoothly. Over the years, Jiangmen Meixin has likely encountered various challenges, providing its team with the expertise to quickly identify and resolve issues. This capability not only enhances production quality but also shortens lead times, making the company more competitive in the marketplace. As a result, the impact of experience on production quality is profound, making Jiangmen Meixin a leader in the brush machine manufacturing sector.

Emerging Trends in Cleaning Technology

As the demand for effective cleaning solutions continues to rise, the cleaning technology industry is witnessing a surge in innovation. One notable trend is the increased integration of automation and robotics in brush machine manufacturing. This evolution allows for improved efficiency and precision, making production processes faster and resulting in higher-quality cleaning tools. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., with over 37 years of experience, are leading the way in adopting cutting-edge technologies that streamline operations.

Sustainability is another crucial trend shaping the future of cleaning technology. Manufacturers are increasingly focusing on eco-friendly materials and energy-efficient machines to reduce the environmental impact of their products. The transition to biodegradable bristle materials and more sustainable manufacturing processes not only caters to consumer demand for greener alternatives but also aligns with global efforts to reduce waste and pollution in the industry. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. is dedicated to pioneering practices that contribute to a cleaner planet.

Moreover, advancements in data analytics and smart technology are revolutionizing how brush machines are used in various cleaning applications. The ability to collect and analyze data from cleaning processes enables operators to optimize performance and maintenance schedules. This shift towards smart cleaning technologies, including Internet of Things (IoT) connectivity, enhances the effectiveness and reliability of brush machines. As industries seek more efficient and effective cleaning solutions, the innovations led by companies like Jiangmen Meixin will play a crucial role in shaping the future of cleaning technology.

Future Directions for Brush Machine Manufacturing

As the demand for more efficient and versatile brush production increases, manufacturers like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are focusing on enhancing the capabilities of their machines. The integration of advanced technology such as automation and robotics is paving the way for streamlined operations and reduced labor costs. Future innovations will likely include smart machines that can adjust their settings autonomously based on production requirements, leading to increased efficiency and output.

Moreover, sustainability is becoming a significant concern in manufacturing processes. In response, brush machine manufacturers are exploring eco-friendly materials and energy-efficient machinery that minimize environmental impact. The adoption of recyclable materials in brush production and the incorporation of features that reduce energy consumption will not only meet regulatory requirements but also satisfy consumer preferences for sustainable products.

Finally, the customization of brush machines to cater to specific industry needs represents a promising direction for the future. Companies are investing in research and development to create modular machines that can be easily adapted for different brush types and manufacturing processes. This flexibility will allow manufacturers to quickly respond to market changes and consumer demands, ensuring that they remain competitive in a rapidly evolving landscape.

Report this page